Why Industrial Aluminum Profiles Are the Backbone of Modern Manufacturing

2025-05-08

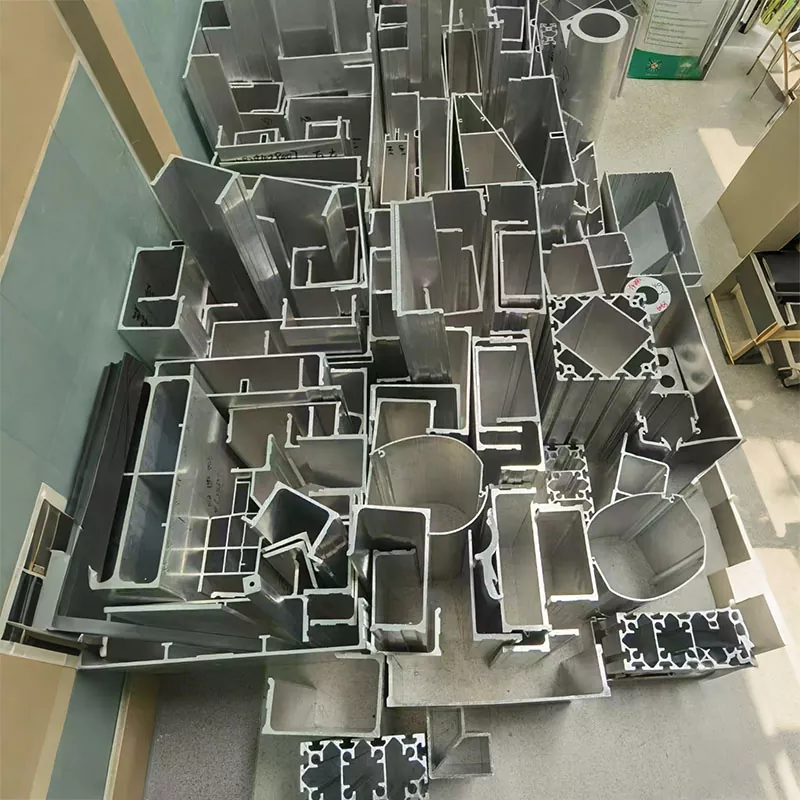

In the fast-paced world of manufacturing, versatility and efficiency are essential. This is where industrial aluminum profiles shine. These modular, lightweight, and durable components have become the preferred building blocks for countless applications, from machine frames to conveyor systems.

1. What Are Industrial Aluminum Profiles?

Industrial aluminum profiles are extruded aluminum components, typically shaped with T-slots. These slots allow for easy attachment of parts, making them incredibly modular. Unlike traditional steel frameworks, aluminum profiles offer both structural integrity and adaptability.

2. Advantages Over Other Materials

Lightweight Yet Strong: Aluminum provides excellent strength-to-weight ratio, making structures easier to handle without sacrificing durability.

Corrosion Resistance: Naturally resistant to rust and corrosion, aluminum profiles are ideal for humid or chemical-exposed environments.

Customizability: The T-slot system allows rapid assembly and reconfiguration with minimal tools or machining.

Cost-Effective: Reduced labor and installation time means lower overall costs in long-term projects.

3. Common Applications

Automation Systems: Machine guards, frames, and robotic arms.

Workstations and Benches: Ergonomic workspaces for industrial and lab use.

Transportation Lines: Modular conveyor systems and material handling solutions.

Cleanroom Structures: Non-contaminating aluminum is perfect for food, medical, and electronic applications.

4. Sustainability and Recycling

Aluminum is 100% recyclable without losing its properties. Using industrial aluminum profiles contributes to a more sustainable production cycle, making them a smart choice for eco-conscious manufacturers.

Whether you’re upgrading a production line or building custom machinery, industrial aluminum profiles provide unmatched adaptability and performance. Their lightweight nature, ease of assembly, and durability make them a foundational element in modern industrial design.