How a CO2 laser cutting machine typically works

2023-10-16

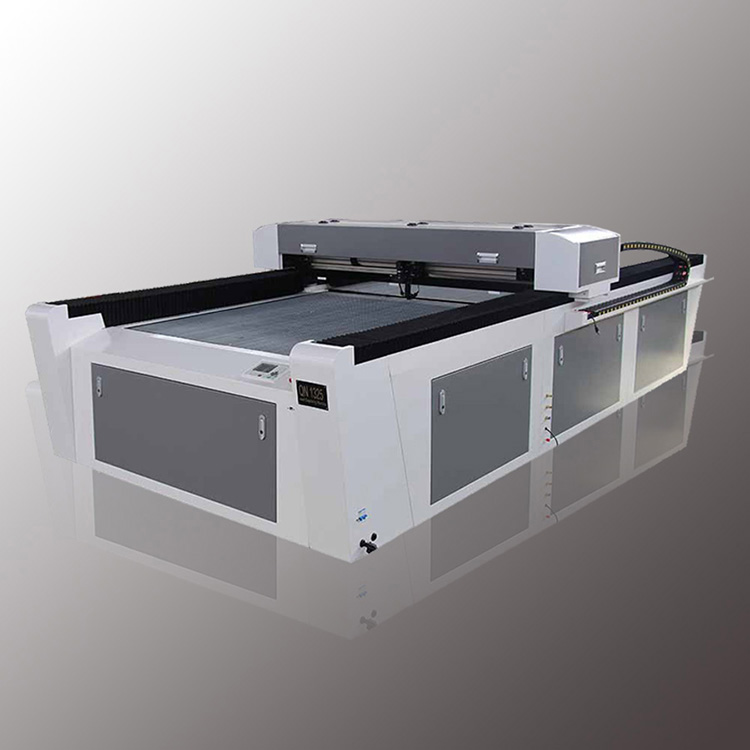

A CO2 laser cutting machine is a type of laser cutting equipment that utilizes a high-powered carbon dioxide (CO2) laser beam to cut through various materials. It is widely used in industries such as manufacturing, automotive, signage, textiles, and more for precise and efficient cutting of materials.

Here's an overview of how a CO2 laser cutting machine typically works:

1. Laser Generation: The CO2 laser cutting machine consists of a CO2 laser tube that produces a highly focused laser beam. This beam is generated by exciting a mixture of carbon dioxide, nitrogen, and other gases within the laser tube using an electrical discharge.

2. Beam Delivery: The laser beam is directed and guided by a system of mirrors to the cutting head, which contains focusing lenses and nozzles. The lenses concentrate the laser beam to a small focal point, increasing its power density.

3. Material Interaction: The focused CO2 laser beam interacts with the material being cut. The intense heat of the laser beam rapidly heats and vaporizes the material at the point of contact, creating a narrow cut or kerf. The laser beam essentially melts or evaporates the material along the cutting path.

4. CNC Control: A computer numerical control (CNC) system controls the movement of the laser cutting machine. The CNC software precisely guides the laser beam along the desired cutting path, following the instructions from a digital design file. This allows for highly accurate and complex cuts to be made on the material.

5. Material Compatibility: CO2 laser cutting machines can cut a wide range of materials, including metals (such as steel, stainless steel, and aluminum), plastics, wood, fabric, leather, paper, and more. The compatibility of materials depends on their ability to absorb the CO2 laser wavelength, as well as factors like thickness and composition.

Advantages of CO2 Laser Cutting Machines:

- Versatile Cutting: CO2 laser cutting machines can cut through a wide variety of materials with high precision and speed.

- High Precision: The focused laser beam enables intricate and detailed cuts, allowing for complex shapes and designs.

- Non-contact Process: The material being cut is not physically touched, reducing the risk of damage or contamination.

- Minimal Heat Transfer: CO2 lasers are relatively efficient at converting electrical energy into laser energy, minimizing heat transfer to the surrounding material.

- Automation: CNC control enables automated cutting processes, reducing labor requirements and ensuring consistent results.

CO2 laser cutting machines are commonly used for applications such as cutting metal sheets, fabricating automotive components, creating intricate designs on acrylic or wood, producing signage, and more. They provide a reliable and precise solution for various industrial cutting needs.