Characteristics of duplex steel flanges

2023-10-16

Duplex steel flanges are a type of pipe fitting used in piping systems to connect pipes, valves, pumps, and other equipment. They are made from duplex stainless steel, which is a family of stainless steels known for their exceptional corrosion resistance and high strength. Duplex stainless steels are characterized by a dual microstructure that consists of both austenitic and ferritic phases, which contributes to their unique combination of properties.

Here are some key features and characteristics of duplex steel flanges:

1. Corrosion Resistance: Duplex stainless steel flanges offer excellent corrosion resistance, making them suitable for use in aggressive environments, such as those containing chloride ions, acids, and seawater. They are often used in offshore and marine applications.

2. High Strength: Duplex steel has higher strength compared to austenitic stainless steels, which allows for the use of thinner-walled pipes and flanges while maintaining structural integrity.

3. Good Toughness: Duplex steel flanges exhibit good toughness, which means they can withstand impact and thermal shocks, making them suitable for cryogenic applications.

4. Weldability: While welding duplex stainless steel can be more challenging than austenitic stainless steel, modern welding techniques and filler materials have improved the weldability of duplex steel flanges.

5. Resistance to Stress Corrosion Cracking: Duplex stainless steels are resistant to stress corrosion cracking (SCC), which is a type of corrosion that can occur under certain conditions in chloride-rich environments.

6. Wide Temperature Range: Duplex steel flanges have good mechanical properties over a wide temperature range, making them suitable for both cryogenic and high-temperature applications.

7. Cost-Efficiency: The use of duplex steel flanges can lead to cost savings in some applications due to their higher strength, which allows for the use of smaller and lighter components.

Common types of duplex stainless steel used for flanges include:

- Duplex 2205 (UNS S32205): This is one of the most widely used duplex stainless steels and is known for its excellent corrosion resistance and high strength. It contains approximately 22% chromium and 5% nickel.

- Super Duplex 2507 (UNS S32750): Super duplex stainless steel offers even higher corrosion resistance and strength compared to Duplex 2205. It contains around 25% chromium and 7% nickel.

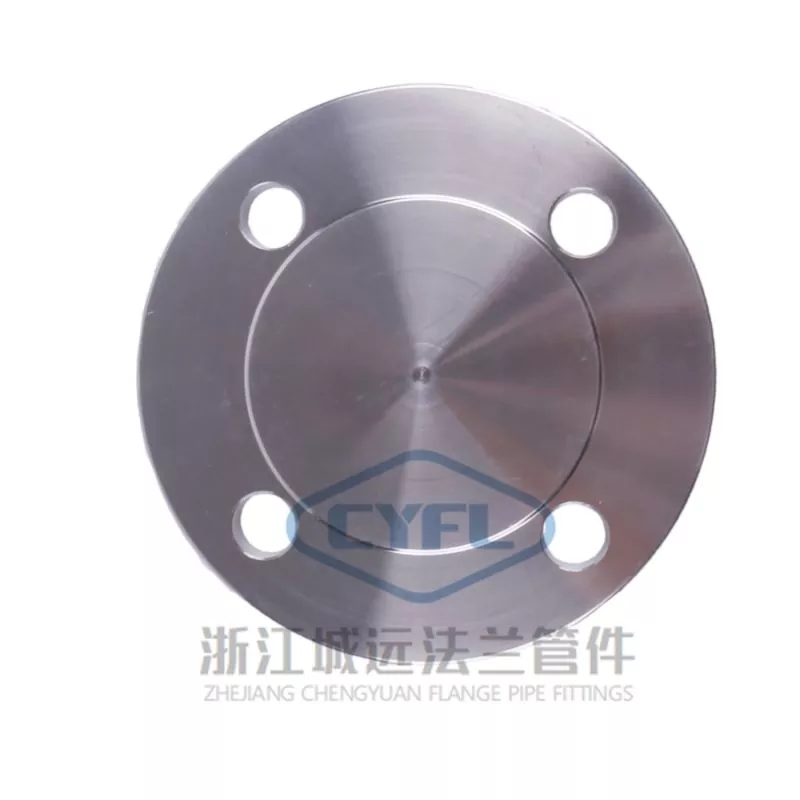

Duplex steel flanges come in various types and classes to suit different pressure and temperature requirements in piping systems. Some common types of duplex steel flanges include weld neck flanges, slip-on flanges, socket weld flanges, blind flanges, and threaded flanges.

When selecting duplex steel flanges for a specific application, it's essential to consider factors such as the corrosive environment, pressure, temperature, and compatibility with other materials in the piping system. Proper material selection, fabrication, and installation are critical to ensuring the long-term performance and integrity of the system.