What is PEEK 3D printer filament?

2023-10-16

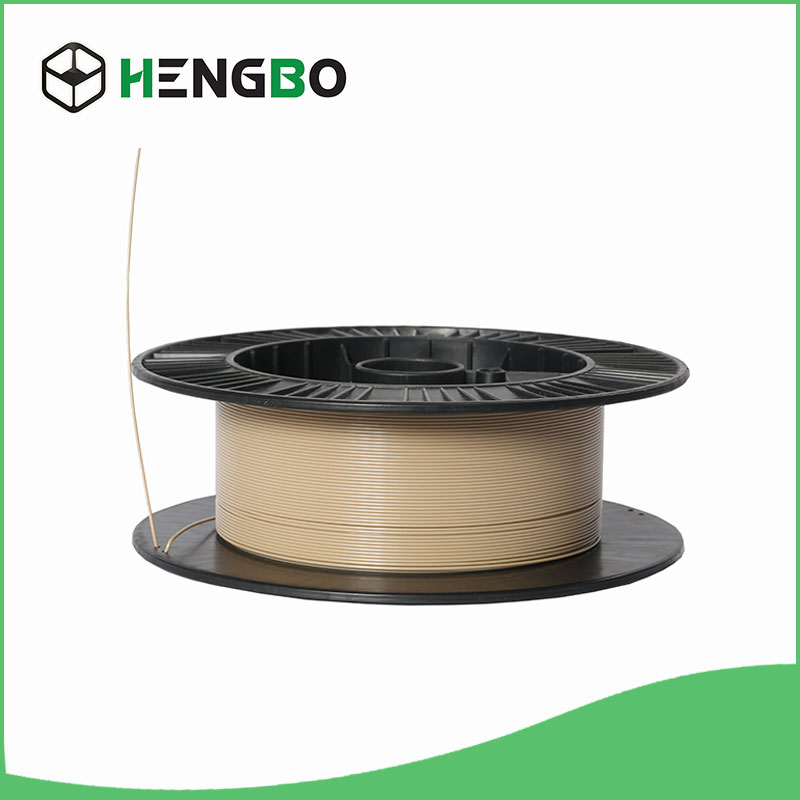

PEEK (Polyetheretherketone) is a high-performance thermoplastic polymer that has gained popularity in the field of 3D printing. PEEK 3D printer filament refers to the filament made from PEEK material that is specifically designed for use in 3D printers.

PEEK is known for its exceptional mechanical properties, high thermal stability, chemical resistance, and excellent electrical insulation properties. These characteristics make it suitable for demanding applications in industries such as aerospace, automotive, medical, and engineering.

When used as a filament in 3D printing, PEEK offers several advantages:

1. High Temperature Resistance: PEEK can withstand high temperatures up to around 250-300°C (482-572°F) without losing its mechanical properties. This property allows PEEK filament to be used in applications that require resistance to heat, such as in aerospace components and industrial machinery.

2. Mechanical Strength: PEEK has excellent mechanical properties, including high tensile strength, stiffness, and impact resistance. As a 3D printing filament, it can produce durable and strong parts suitable for load-bearing applications.

3. Chemical Resistance: PEEK is highly resistant to a wide range of chemicals, including acids, bases, and many organic solvents. This makes it suitable for applications that involve exposure to corrosive environments or chemical processing.

4. Electrical Insulation: PEEK is an excellent electrical insulator, making it suitable for components that require electrical isolation or insulation properties, such as electrical connectors or insulating parts.

Using PEEK filament in 3D printing requires a 3D printer with a heated build chamber and a hot end capable of reaching the high temperatures required to melt and extrude the material. Due to its high melting point and thermal properties, printing with PEEK can be challenging and may require specialized equipment and expertise.

PEEK 3D printer filament opens up possibilities for creating functional prototypes, custom parts, and end-use products that demand high performance and withstand harsh environments. However, it is important to note that PEEK filament tends to be more expensive compared to standard filaments, and the printing process may require additional considerations and expertise.