OEM UL FM Gate Valve: Essential Features and Industrial Applications for Superior Flow Control

2025-12-23

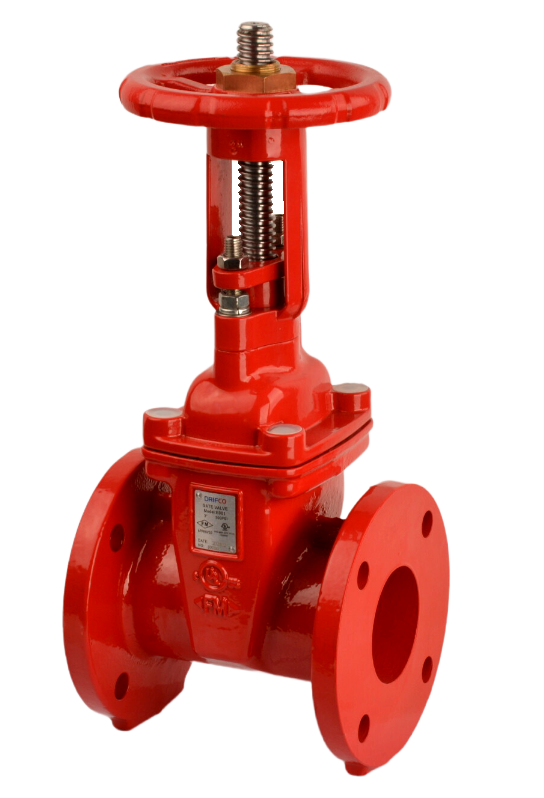

In the complex world of industrial flow control, where precision and reliability are non-negotiable, the OEM UL FM Gate Valve stands as a critical component for managing fluid systems efficiently. At DRIFCO, we recognize that superior performance starts with understanding the essential features and versatile applications of these valves, which are engineered to ensure seamless operations across various demanding environments. This blog delves into what makes these valves indispensable for industries ranging from fire protection to chemical processing, highlighting their role in enhancing safety and operational efficiency. Join us as we explore the innovative design and robust capabilities that set these valves apart, offering practical insights for professionals looking to optimize their flow control solutions.

Unveiling the Core Engineering of OEM UL FM Gate Valves

When it comes to OEM UL FM gate valves, the core engineering often lies beneath the surface—quite literally. These valves aren't just off-the-shelf products; they're engineered from the ground up to meet rigorous standards like Underwriters Laboratories (UL) and Factory Mutual (FM) certifications. What sets them apart is the precision in material selection, such as using corrosion-resistant alloys or specialized coatings that withstand harsh industrial environments. The design process involves extensive testing for fire safety, flow control, and durability, ensuring they perform reliably under pressure. This attention to detail means that every component, from the gate mechanism to the seals, is tailored for seamless integration into larger systems, reducing downtime and maintenance costs.

Beyond mere compliance, the innovative engineering of these valves focuses on enhancing operational efficiency. Many incorporate features like low-torque operation, which allows for easier manual handling or reduces strain on automated actuators. Advanced flow dynamics are modelled using computational fluid dynamics (CFD) to minimize turbulence and pressure drops, optimizing energy usage in pipelines. These subtle yet critical adjustments make a significant difference in real-world applications, where even minor improvements can lead to substantial savings in fuel or electricity over time. It's this blend of certified safety and smart design that gives OEM UL FM gate valves a competitive edge.

Perhaps the most overlooked aspect is the customization potential inherent in their engineering. Unlike generic valves, OEM versions are often developed in close collaboration with clients to address specific challenges, such as handling unique fluid types or fitting into tight spaces. This collaborative approach ensures that the valve not only meets regulatory benchmarks but also aligns perfectly with the client's operational needs. By prioritizing adaptability and long-term performance over one-size-fits-all solutions, these engineered valves become integral to safer, more efficient industrial processes worldwide.

Precision Flow Management with Advanced Valve Technology

Precision flow management leverages advanced valve technology to enable meticulous control over fluid dynamics in industrial systems. Unlike conventional valves that often rely on basic mechanical adjustments, modern solutions integrate smart sensors and real-time feedback mechanisms. This allows operators to fine-tune flow rates with unprecedented accuracy, minimizing waste and optimizing performance. For instance, in chemical processing plants, even minor fluctuations can affect product quality; advanced valves maintain consistent flow, ensuring reliable outcomes and reducing the need for manual oversight.

What sets this technology apart is its ability to adapt to dynamic conditions. Advanced valves often incorporate materials like corrosion-resistant alloys or ceramics, enhancing durability in harsh environments. They also feature modular designs that simplify maintenance and upgrades, cutting downtime. In applications such as water treatment or oil refining, this translates to smoother operations and lower long-term costs, as components withstand wear and exposure to aggressive substances.

Looking ahead, innovations in valve technology continue to push boundaries. Some systems now embed AI algorithms that predict flow patterns and adjust settings proactively, further boosting efficiency. By combining robust engineering with intelligent control, precision flow management not only meets today's industrial demands but also paves the way for more sustainable and automated processes globally.

Exploring Key Specifications and Material Durability

When diving into the world of product design or selection, the specifications and durability of materials often emerge as pivotal factors that can make or break a project's success. Key specifications, such as dimensions, weight, and performance metrics, serve as the blueprint for ensuring compatibility and functionality in various applications. Meanwhile, material durability isn't just about longevity; it's a complex interplay of factors like tensile strength, corrosion resistance, and environmental adaptability. For instance, in construction or automotive industries, choosing a material with high durability can significantly reduce maintenance costs and enhance safety over time.

Delving deeper, durability goes beyond mere toughness—it involves understanding how materials react under stress, exposure to elements, and daily wear. Innovative materials, such as composites or advanced polymers, are engineered to withstand extreme conditions while meeting strict specifications. This focus on durability often involves rigorous testing, like accelerated aging or impact simulations, to predict real-world performance. By prioritizing these aspects, manufacturers can create products that not only meet initial specs but also deliver reliable, long-term value in demanding environments.

Ultimately, exploring key specifications and material durability is about striking a balance between technical requirements and practical resilience. It's a thoughtful process that considers everything from cost-effectiveness to sustainability, ensuring that choices align with both immediate needs and future challenges. In today's fast-paced market, this holistic approach can set products apart, offering customers confidence in their investments and fostering trust through demonstrated durability and adherence to precise specifications.

Industrial Applications Across Critical Sectors

In today's interconnected world, industries from manufacturing to energy rely heavily on advanced technologies to drive efficiency and innovation. For instance, in the manufacturing sector, smart factories leverage IoT sensors and robotics to optimize production lines, reducing downtime and enhancing quality control. Similarly, the energy sector utilizes predictive analytics and grid management systems to balance supply and demand, ensuring stable power distribution while integrating renewable sources. These applications not only boost productivity but also contribute to sustainability goals, making them indispensable in modern industrial landscapes.

Beyond traditional fields, critical sectors like healthcare and agriculture are transforming through industrial applications. In healthcare, precision medicine and automated diagnostic tools revolutionize patient care by providing personalized treatments and faster diagnoses. Agriculture benefits from drone-based monitoring and automated irrigation systems, which increase crop yields and conserve resources. By adopting these technologies, these sectors enhance their resilience and adaptability, addressing global challenges such as food security and public health with greater precision and impact.

Furthermore, the transportation and logistics sectors are experiencing a paradigm shift with industrial applications. Autonomous vehicles and real-time tracking systems streamline supply chains, reducing delays and costs while improving safety. In aerospace, advanced materials and simulation tools enable more efficient and durable aircraft designs. These innovations underscore how industrial applications permeate critical sectors, fostering a more connected and responsive global economy that thrives on continuous improvement and technological integration.

Enhancing Operational Efficiency and Safety Standards

When we talk about boosting operational efficiency, it's not just about cutting costs or speeding up processes—it's about creating a seamless workflow where every piece of the puzzle fits perfectly. By integrating smart technologies and streamlining communication channels, organizations can reduce downtime, minimize errors, and ensure that resources are allocated where they're needed most. This proactive approach not only enhances productivity but also sets the stage for a safer work environment by eliminating bottlenecks and reducing the likelihood of accidents caused by rushed or inefficient procedures.

Safety standards are the backbone of any successful operation, and elevating them goes beyond mere compliance. It involves fostering a culture where every team member feels empowered to identify risks and suggest improvements. By investing in continuous training, leveraging real-time data analytics, and implementing robust safety protocols, companies can create an environment where safety is ingrained in daily practices. This commitment not only protects employees but also enhances operational efficiency by preventing costly disruptions and building trust with clients and stakeholders.

The synergy between enhanced operational efficiency and elevated safety standards is where true transformation happens. Rather than viewing these elements as separate goals, forward-thinking organizations recognize that they reinforce each other. Efficient systems reduce the strain on workers, making it easier to adhere to safety guidelines, while a strong safety culture encourages careful planning and attention to detail that boosts overall performance. By aligning these efforts, businesses can achieve a competitive edge, delivering reliable results while prioritizing the well-being of their people and the integrity of their operations.

Customizable Solutions for Diverse Flow Control Needs

When it comes to managing flow across various industrial or commercial systems, one size definitely does not fit all. Our approach centers on developing tailored solutions that adapt to the unique demands of each application—whether you're handling high-viscosity fluids in chemical processing or requiring precise regulation in water treatment. By working closely with clients to understand their specific challenges, we ensure that every component, from valves to pumps, is optimized for performance, durability, and cost-efficiency, making your operations smoother and more reliable.

Unlike off-the-shelf products that can force compromises, our customizable options allow for adjustments in materials, sizes, and control mechanisms. For instance, in sectors like oil and gas or pharmaceuticals, where safety and precision are non-negotiable, we integrate advanced sensors and automated controls that respond in real-time to changing conditions. This flexibility not only enhances system resilience but also future-proofs your setup, enabling easy upgrades as technology or requirements evolve without overhauling the entire infrastructure.

Ultimately, our commitment to diverse flow control translates into solutions that boost productivity and reduce downtime. By focusing on user-centric design, we deliver systems that are intuitive to operate and maintain, backed by ongoing support to ensure long-term success. This hands-on, collaborative method sets us apart, turning complex flow management into a streamlined advantage for your business.

FAQ

OEM UL FM Gate Valves are designed with robust materials like cast iron or stainless steel, offering high durability and corrosion resistance, which are critical for handling fluids in harsh environments such as chemical plants or water treatment facilities. They ensure reliable shut-off and superior flow control.

The OEM UL FM certification signifies that these gate valves meet stringent safety and performance standards set by Underwriters Laboratories and FM Global. This ensures they can withstand extreme pressures and temperatures, reducing the risk of leaks or failures in critical industrial operations.

These valves are widely used in sectors like oil and gas, power generation, and manufacturing due to their ability to manage high-pressure flows and provide precise control. Their certification makes them ideal for applications where safety and compliance with regulations are paramount.

Features such as a wedge or parallel disc design, along with tight sealing mechanisms like resilient seats, enable smooth operation and minimal flow resistance. This allows for efficient regulation of fluid movement, enhancing overall system performance.

Compared to standard valves, OEM UL FM Gate Valves often require less maintenance due to their high-quality construction and corrosion-resistant coatings. They typically have a longer service life, making them a cost-effective choice for long-term industrial use.

Best practices include proper alignment during installation, regular lubrication of moving parts, and routine inspections for wear or damage. Following manufacturer guidelines and using compatible accessories can maximize efficiency and prevent operational issues.

Yes, these valves can be customized with options like different materials (e.g., bronze for specific fluid compatibility), actuator types (manual or automated), and sizes to fit unique system requirements, enhancing flexibility across various applications.

By providing reliable shut-off capabilities and precise flow regulation, these valves help prevent accidents like spills or overflows. Their certified design boosts system efficiency, ensuring smooth operations and reducing downtime in industrial settings.

Conclusion

OEM UL FM gate valves represent a pinnacle of flow control engineering, combining rigorous standards from Underwriters Laboratories (UL) and Factory Mutual (FM) with innovative design. These valves are engineered for precision flow management through advanced technology like tapered wedges and self-cleaning seats, ensuring reliable shut-off even under high-pressure conditions. Their durability stems from robust materials such as stainless steel or bronze, chosen to withstand corrosive environments and extreme temperatures. Key specifications often include fire-safe designs and anti-static features, making them indispensable in scenarios demanding both performance and safety. By integrating these elements, OEM UL FM gate valves deliver superior control, minimizing leakage and enhancing operational stability across various industrial settings.

The industrial applications of OEM UL FM gate valves span critical sectors including oil and gas, chemical processing, water treatment, and fire protection systems. In these environments, they enhance operational efficiency by reducing downtime through quick actuation and minimal maintenance needs. Customizable solutions allow for adaptation to diverse flow control requirements, such as varying pipe sizes or specific fluid types, ensuring optimal performance tailored to each application. By adhering to high safety standards, these valves not only improve process reliability but also contribute to regulatory compliance and risk mitigation. Ultimately, their versatility and resilience make them a key component in achieving seamless, safe, and efficient flow management in demanding industrial operations.

Contact Us

Contact Person: George

Email: [email protected]

Tel/WhatsApp: 13863633883

Website: https://www.es-fire.com